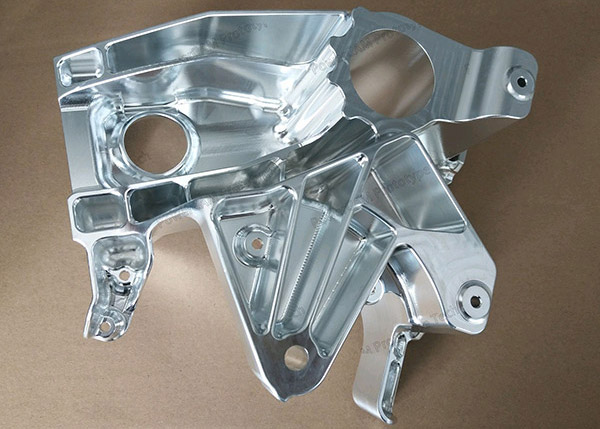

Custom magnesium alloy parts and magnesium alloy rapid prototype

The density of magnesium alloy is 1.8g/cm3, which is the lightest metal. The proportion of magnesium is about 2/3 of that of aluminum, which is 1/4 of that of iron. If you would like to customized product to have both: light weight, high strength, high Rigidity, good heat dissipation, ability to withstand impact loads greater than aluminum alloys, good corrosion resistance to organics and alkalis, then magnesium alloys are a very good choice, but also because of its advantages, magnesium alloy parts in new energy vehicles, pharmaceuticals Applications in the chemical, aerospace, aerospace, 3C products, robotics, etc. are very effective!

What are the surface treatments used for magnesium machined parts and magnesium prototype?

Magnesium alloys are active metals that can produce chemical reactions in the air. They require corresponding requirements for the processing, environmental, water, and chemical raw materials processes. Therefore, the surface treatment effects that magnesium alloys can now perform are: Microarc oxidation of magnesium alloys. , Magnesium alloy plating, magnesium alloy spray paint, magnesium alloy spray powder, magnesium alloy passivation and so on.

The advantages of magnesium alloy parts in industrial manufacturing

Application in aerospace

Magnesium alloys are the lightest metal structural materials used in the aerospace and aerospace manufacturing industries. They have high vibration resistance and good heat absorption properties. They are very good materials for the manufacture of aircraft hubs. They are also suitable for the manufacture of engine gearboxes, oil pumps and Components such as tubing, rocker arms, flaps, doors, and rudder, as well as some components on satellites, such as instrumentation bays, tail cabins, and engine mounts, use magnesium alloys

(1) Shell class. Such as clutch housing, valve cover, instrument panel, gearbox body, crankcase, engine front cover, cylinder head, air conditioner housing, etc.

(2) stents. Such as steering wheel, steering bracket, brake bracket, seat frame, mirror bracket, distribution bracket and so on.

According to the relevant research, the reduction in vehicle self-respect, fuel and emissions will be reduced accordingly, each reduction of 10%, so reducing the impact of car weight on the environment and energy is very large,

Application on digital SLR cameras

Due to its low density and high strength, magnesium alloys have certain anti-corrosion properties and are commonly used as skeletons for SLR cameras. General high-end and professional digital SLR cameras are made of magnesium alloy as the skeleton, making it robust and durable. Digital SLR cameras using a magnesium alloy body are not only a symbol of a quasi-professional level, but also have a high price.

other apps

»» Mobile Phones, Laptops, TV Cases With the changing size of LCD screens, magnesium alloys have been used on the support frames and housings.

»» Magnesium alloys are used on housings and heat-dissipating parts such as computers and projectors that generate high temperatures internally, and magnesium alloys can eliminate the need for heat sinks.

»» Magnesium alloys have better electromagnetic wave shielding performance than plastics, and the use of magnesium alloys eliminates electroplating of electromagnetic wave shielding films.

»» Magnesium alloys are used on the steering wheel and seats to increase impact absorption and reduce weight when the car is hit.

»» Magnesium alloy is used as a robot part. Its light weight can reduce the inertia of motion and improve the operating efficiency and movement accuracy.

What are the machining processes for custom magnesium alloy products?

Magnesium parts and aluminum prototype produced by PowerCAM Precision can be manufactured in all kind of different processes using low-volume production methods such as: CNC milling, CNC lathe machining, wire cutting, spark, drilling, tapping, bracing, etc. .